Counterfeiting has become a pervasive problem that threatens various industries, from electronics to pharmaceuticals. In response to this global menace, holographic solutions have emerged as one of the most effective anti-counterfeiting measures. These solutions offer enhanced product security, brand protection, and consumer trust.

In this blog, we will explore the benefits of holographic solutions, the different types available, successful integration strategies, consumer education, and the promising future of this technology in manufacturing.

Introduction to Holographic Solutions

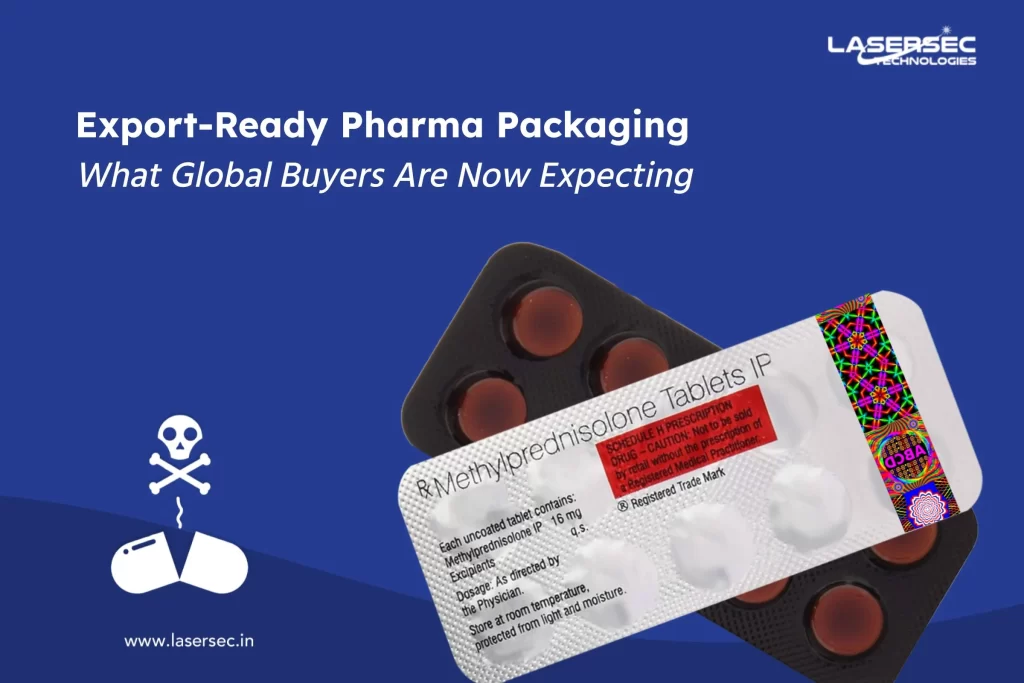

Holographic solutions are cutting-edge technologies that offer unique visual effects, making them incredibly difficult to replicate. These holograms possess three-dimensional depth, making them visually striking and captivating. Manufacturers use specialized equipment to create holographic images, incorporating custom designs, security features, and microtext, making them virtually impossible to duplicate through traditional printing methods.

Benefits of Holographic Solutions:

Implementing holographic solutions in manufacturing yields numerous benefits. Firstly, holograms provide a robust anti-counterfeiting defense, deterring counterfeiters with their complexity. Secondly, they bolster brand protection by enhancing the perception of authenticity among consumers. Thirdly, these solutions build consumer trust, assuring buyers that they are purchasing genuine, high-quality products. Moreover, holographic solutions reduce the risks of legal entanglements related to counterfeit goods.

Types of Holographic Solutions:

Manufacturers can choose from a variety of holographic technologies, each tailored to meet specific needs. Two-dimensional and three-dimensional holograms offer captivating visual effects, which are challenging for counterfeiters to replicate accurately.

Dot matrix holograms, on the other hand, present a pixelated appearance when viewed from different angles, providing an additional layer of complexity. Flip-flop holograms exhibit color shifts when tilted, adding a dynamic element to the security feature. Custom holograms can integrate the manufacturer’s logo, unique patterns, or text, ensuring a one-of-a-kind solution that maximizes product security.

Integration into the Manufacturing Process:

Successfully integrating holographic solutions into the manufacturing process requires careful planning and collaboration with hologram providers. Manufacturers should conduct thorough risk assessments to identify vulnerable points in their supply chains. Working closely with experienced holographic solution experts, manufacturers can embed holograms into packaging, labels, or directly onto the product. Seamless integration enhances the hologram’s visibility, ensuring consumers can easily verify product authenticity.

Customization and Design:

Customization is a critical aspect of holographic solutions in manufacturing. Manufacturers can collaborate with hologram providers to design unique holograms that represent their brand and product characteristics. Custom elements, such as logos, serial numbers, or intricate patterns, further elevate the level of security, making it harder for counterfeiters to reproduce the hologram.

Combining Holographic Solutions with other Anti-Counterfeiting Technologies:

While holographic solutions provide robust protection, combining them with other anti-counterfeiting technologies enhances the overall security. Integrating holograms with RFID tags, QR codes, and security inks creates a multi-layered defense against counterfeiters. Each technology complements the other, augmenting the complexity of the security features and making counterfeiting even more challenging.

Future Trends and Innovations:

As technology continues to evolve, so will holographic solutions. Future trends may include advancements in hologram design, increased use of nanotechnology for even more intricate security features, and integration with blockchain technology for enhanced traceability. These innovations promise a future where counterfeiting becomes increasingly difficult, empowering manufacturers to protect their brand integrity and consumers to make informed choices.

Implementing holographic solutions in manufacturing is an indispensable step towards combating counterfeiting. The myriad benefits, customizability, and integration possibilities make holograms a potent weapon in the battle against counterfeiters. As technology advances, holographic solutions will undoubtedly continue to play a vital role in securing the authenticity of products and fostering consumer trust.

By collaborating with holography solution manufacturers like Lasersec Technologies, automotive manufacturers can secure their supply chains, protect their brand reputation, and ensure consumer safety.

If you’re a manufacturer or business and looking for smart packaging for your products, look no further than us. We have the knowledge, experience, and expertise to help you to find the best solution that works for your business.

Reach out to us to discuss and our team will provide you with tailored solutions and support to make the process as smooth as possible. We also One Stop Solution to fight against counterfeit and create a more secure environment for your business. With less counterfeiting, you can maintain sales and increase customer trust.

Stay proactive, stay vigilant, and invest in the right anti-counterfeit solutions to ensure a counterfeit-free future.

About Lasersec Technologies

We are one of the leading holographic solutions manufacturing company, that are used as an anti-counterfeiting device. Our R&D team from the production area is constantly dedicated to finding innovative solutions against counterfeits. Thus, we proudly emphasize on the fact that all our solutions are original ones without any interference from any other outside companies. We have successful business alliances located in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, United Kingdom, and countries of Europe.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.