Due to the increase in counterfeit part, there is an impending concern on the reliability of electronic components. The effects of counterfeit elements usually have a brief lifespan which might break the monotonous chain of a system or even cause circumstantial hazards.

The parts might come in for cheap, but the effectiveness of it and its reliability is far from being certain. The various parts which are being counterfeited might vary from scrapped parts to even reclaimed parts.

There are various ways to make a counterfeit part; it can be relabeling or refurbishing or even repackaging. Early fake components could be readily detected by conventional methods, but due to the sophistication of techniques, it can get hard to differentiate.

Detection Process

To counter with such an abomination, the industries can buy directly from any authorized seller or the original manufacturers themselves. These sorts of supplies have its perks and disadvantages as well where the parts will come with an extended warranty, but the supply of stock is very limited and less versatile.

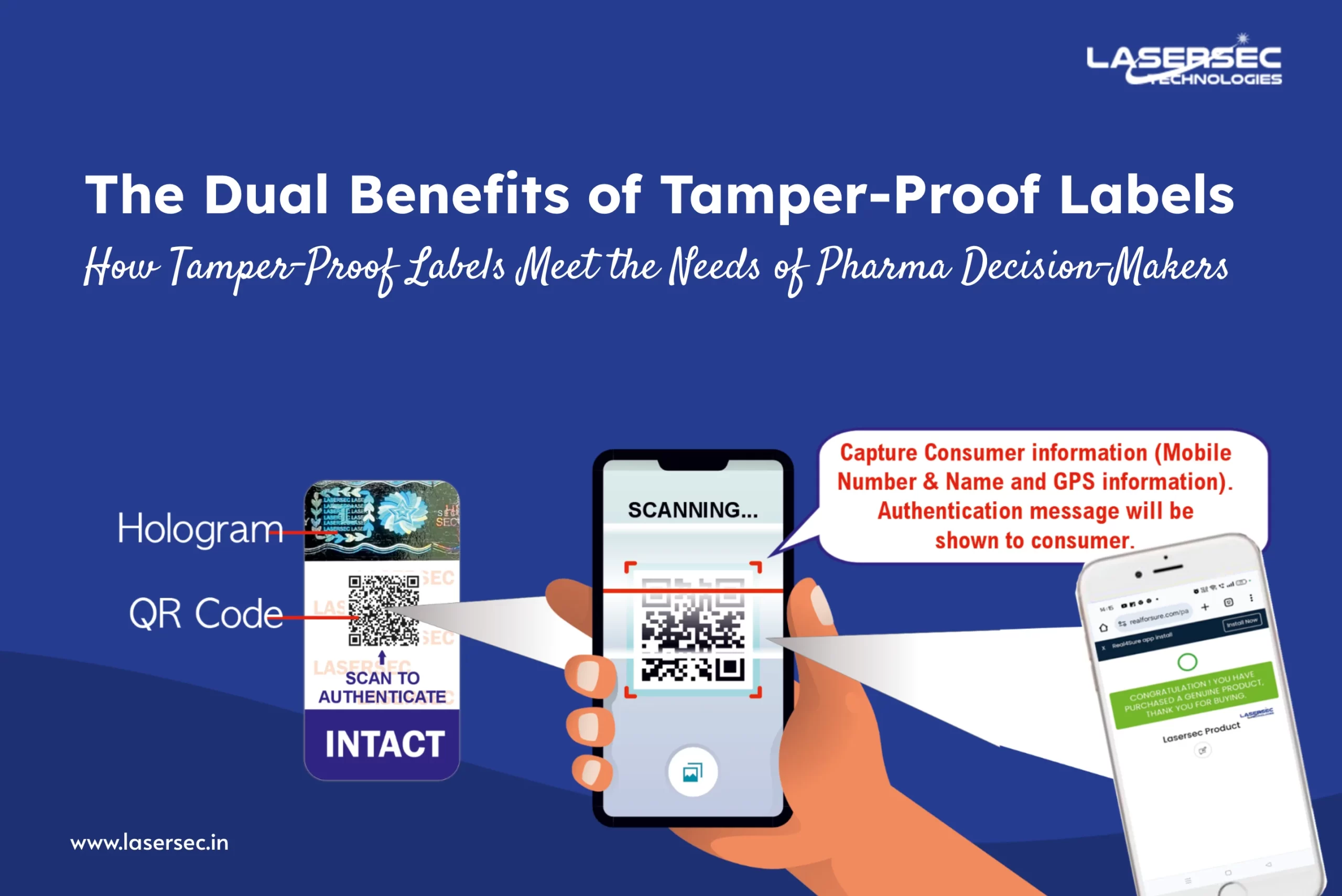

There are various effective ways to stop the supply of counterfeit goods; Proper scrutiny of the products and maintaining the sanctity of the supply chain, authentication, and verification through barcodes which are embedded in a said product.

Most of the high-end parts are being made with highly purified mono-crystalline silicon which is being made in safety rooms under proper surveillance. While on the other hand the counterfeit goods are not made but rather extracted from old parts and relabeled under respective company emblems.

The exclusion of this ambiguity can only come into effect when the supply chains are being thoroughly scrutinized and kept under surveillance from even the low tier end users to even the highest tier end contractors. The government agencies along with the private organizations must work together to combat such nuisance.

-footer.png)