India’s pharmaceutical landscape is undergoing a transformation — and packaging is at the center of it.

With the CDSCO’s new QR code and serialization mandates, every exported pharma product must now be secure, traceable, and tamper-evident.

For manufacturers, especially SMEs, this can feel like a complex compliance challenge.

But there’s a powerful, proven solution already within reach: Holographic Blister Packaging.

1. The New CDSCO Reality

To curb counterfeit drugs and ensure authenticity across the supply chain, the Central Drugs Standard Control Organization (CDSCO) now requires export-bound pharmaceutical products to carry:

- Secure and scannable QR codes

- Unique serialization at batch or unit level

- Tamper-evident features on primary packaging

This means your packaging must do more than look professional — it must communicate trust, security, and transparency to regulators, distributors, and patients worldwide.

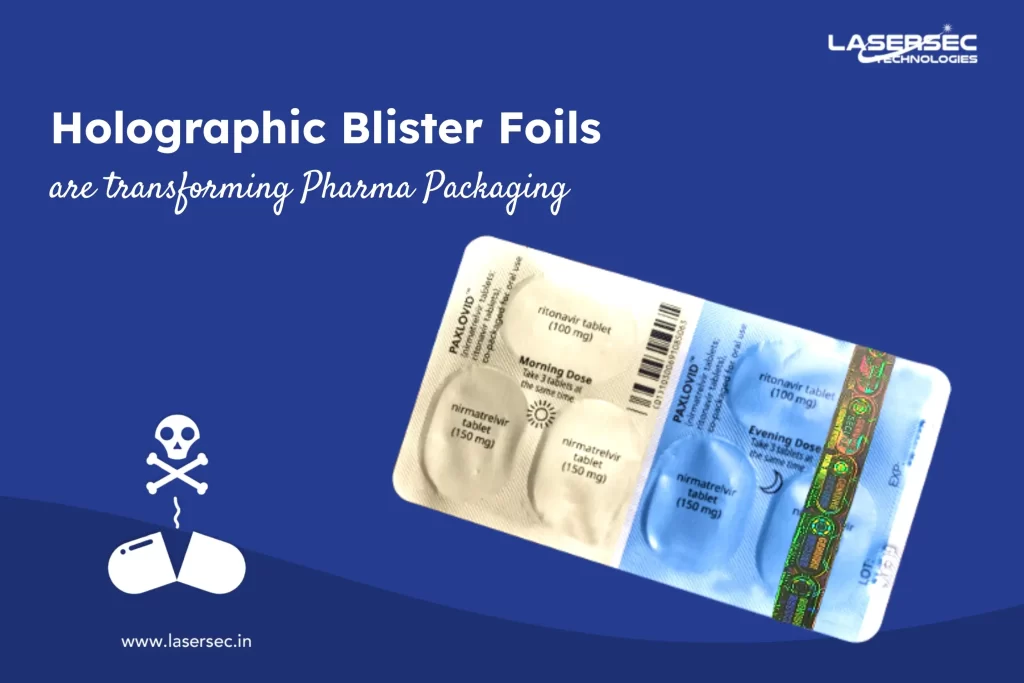

2. Why Holographic Blister Packaging Foils Are the Ideal Fit

Holographic blister foils are designed not just for visual appeal, but for multi-layered protection.

They merge optical security, digital traceability, and physical tamper resistance — all in one compact, cost-effective solution.

Key advantages include:

- Built-in Anti-Counterfeit Security:

Complex holographic patterns, diffractive designs, and hidden laser effects make duplication nearly impossible. - Tamper-Evident Layering:

Any attempt to peel or alter the foil leaves visible damage — ensuring that the product cannot be resealed or reused undetected. - QR & Serialization Integration:

Holographic foils can seamlessly integrate dynamic QR codes and serialized data, allowing regulators and end-users to instantly verify product authenticity. - Regulatory Compliance:

They fulfill the CDSCO’s core requirements — secure labeling, traceability, and anti-tampering — without requiring major production line changes. - Supply Chain Visibility:

When linked to digital Track & Trace systems, each blister pack becomes part of a transparent, verifiable export network.

3. How It Works

Each holographic blister foil is embedded with security layers visible and invisible to the naked eye.

When printed with unique serial numbers or QR codes, it creates a dual-authentication system:

| Layer | Function | Benefit |

| Optical Security (Holography) | Visually identifiable design that’s impossible to replicate | Instant brand and regulatory authentication |

| Digital Security (QR + Serialization) | Unique, scannable identity for every pack | Enables verification and traceability |

| Tamper Evidence | Irreversible visual damage on interference | Prevents resealing or counterfeit replacement |

This layered approach makes it extremely difficult for counterfeiters to reproduce or reuse packaging — offering compliance with confidence.

4. Why SMEs Should Choose Holographic Blister Packaging

Unlike large-scale digital upgrades, holographic blister foils are scalable, adaptable, and cost-efficient.

For SMEs, this means:

- No heavy capital investment in new lines

- Immediate enhancement of regulatory readiness

- Compatibility with existing packaging formats

- Added brand value in export markets

It’s a simple way to make your products CDSCO-compliant and globally credible — without the complexity of building new infrastructure.

5. Beyond Compliance: Building Trust Across Borders

The global pharma supply chain thrives on transparency.

By adopting holographic blister foils, Indian exporters not only meet CDSCO and international labeling mandates but also strengthen brand trust with distributors and healthcare professionals abroad.

- Regulators see transparency.

- Distributors see authenticity.

- Patients see safety.

And your brand earns long-term credibility in every market it reaches.

Secure, Scalable, and Future-Ready

The CDSCO’s labeling mandates are here to stay — but compliance doesn’t have to be complicated.

Holographic blister foils bring together the best of physical and digital protection, offering a ready-to-implement, regulation-compliant, and cost-effective solution for Indian pharma exporters.

At Lasersec Technologies, we specialize in custom-designed holographic blister foils that combine optical security, dynamic QR codes, and tamper-evident protection.

Our solutions are trusted by leading pharmaceutical manufacturers to safeguard brands, meet regulatory standards, and ensure patient safety.

Let’s help you make compliance your competitive edge — one blister pack at a time.