In the pharmaceutical industry, securing products against tampering and counterfeiting is a pressing concern. As counterfeit drugs pose significant risks to patient safety and brand integrity, selecting the right blister foil is crucial for effective packaging security. This blog will explore common threats, the advantages of security-enabled blister foils, and practical tips for manufacturers to make informed choices.

Common Threats in Pharmaceutical Packaging

Pharmaceutical packaging faces various threats, including:

1. Counterfeiting: Unauthorized replicas of drugs can enter the market, endangering patients and damaging brand reputation.

2. Tampering: Products can be altered or contaminated, compromising their safety and efficacy.

3. Improper Storage Conditions: Packaging that fails to protect products from environmental factors can lead to degradation.

Blister foils play a vital role in combating these threats, providing an additional layer of protection that helps ensure product integrity and consumer trust.

Standard vs. Security-Enabled Blister Foils

While standard blister foils offer basic protection, security-enabled blister foils incorporate advanced features designed to deter tampering and counterfeiting. Key differences include:

1. Tamper Evidence: Security-enabled foils show visible signs if tampering occurs, alerting consumers and manufacturers.

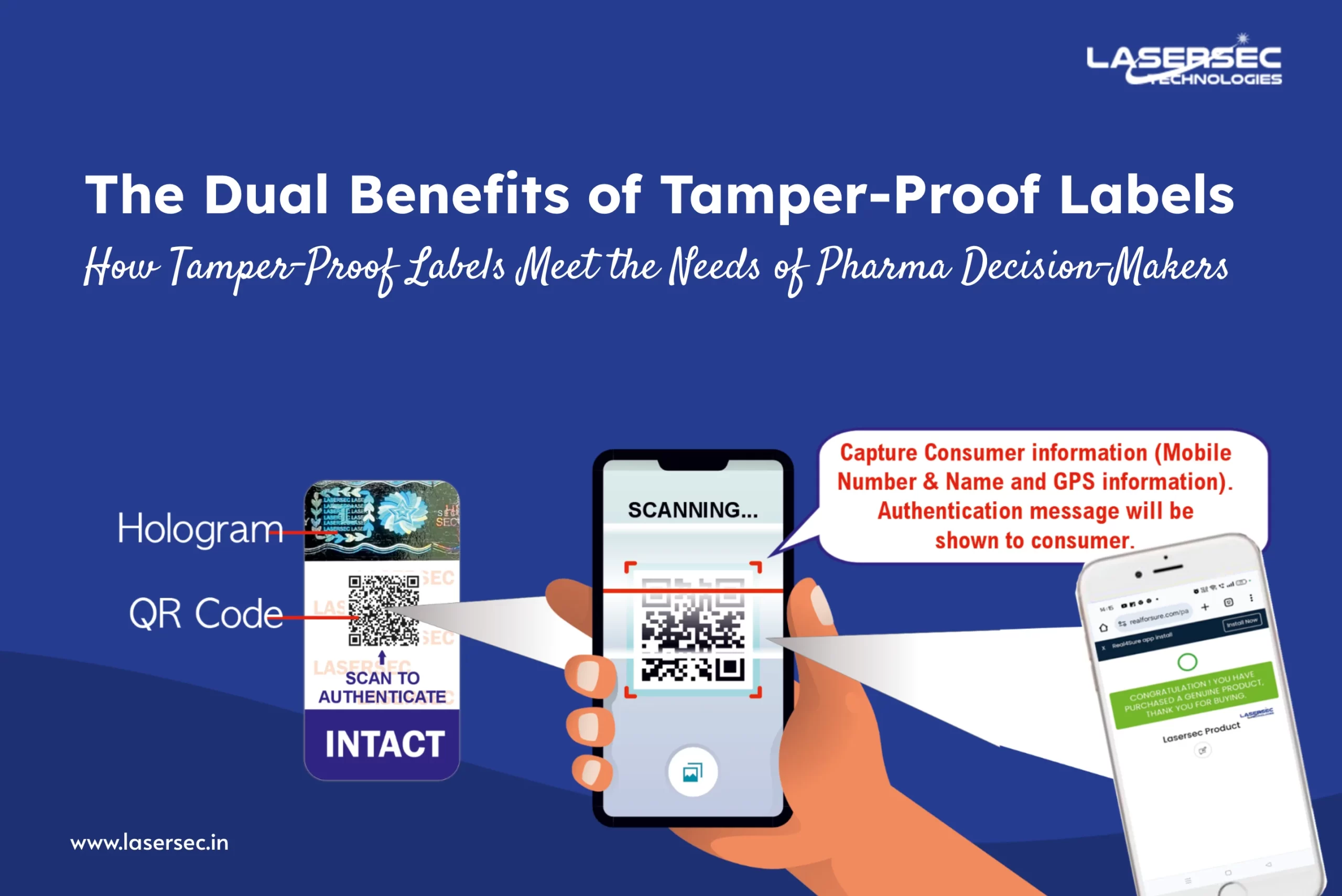

2. Holographic Elements: These unique visual features make replication difficult, adding an extra layer of security.

3. Integrated QR Codes: Allow consumers to verify product authenticity easily, creating a direct connection between manufacturers and customers.

By choosing security-enabled blister foils, manufacturers can enhance their products’ protection and foster consumer confidence.

Enhancing Packaging Security with Holographic Elements and QR Codes

Holographic elements are more than just eye-catching; they serve as effective deterrents against counterfeiting. Their complex patterns and light-reflective properties make it challenging for counterfeiters to replicate packaging accurately. Additionally, integrating QR codes into blister foils allows consumers to authenticate products swiftly, promoting transparency and trust in the supply chain. This dual approach not only enhances security but also improves customer engagement.

The Role of Transparent Holographic Strip Foil in Product Differentiation

Transparent Holographic Strip Foil offers a unique solution for product differentiation. Its visually striking appearance makes products stand out on the shelf while maintaining security. By allowing visibility of the product inside, this foil strikes a balance between aesthetics and protection, appealing to consumers who value both quality and security. This type of foil is particularly useful for premium pharmaceutical products looking to convey a sense of trustworthiness and excellence.

Factors to Consider When Choosing Blister Foils

When selecting the ideal blister foil, manufacturers should consider the following factors:

1. Product Visibility: Ensure the packaging allows consumers to see the product while maintaining security features.

2. Tamper Resistance: Opt for foils that show clear signs of tampering, deterring potential threats.

3. Regulatory Compliance: Verify that the chosen foil meets industry standards and regulations to avoid compliance issues.

Practical Tips for Manufacturers

Here are some practical tips to guide manufacturers in selecting the best blister foil for their needs:

1. Evaluate Cost vs. Benefit: Consider the long-term benefits of investing in security-enabled foils versus the potential costs associated with counterfeiting incidents.

2. Assess Risk Levels: Determine the risk of counterfeiting and tampering for your specific products to inform your foil selection.

3. Consult with Experts: Engage with packaging professionals who can provide insights into the latest technologies and trends in blister foil solutions.

In the ever-evolving landscape of pharmaceutical packaging, the right blister foil is essential for ensuring product safety and consumer confidence. By prioritizing security features like holographic elements and QR codes, manufacturers can effectively combat counterfeiting and tampering while enhancing their brand image.

Contact Us for a Consultation

Looking to customize blister foil solutions for your products? Our team at Lasersec Technologies is here to help! We specialize in providing tailored packaging solutions that meet your unique needs and enhance product security. Let’s work together to protect your brand and ensure the safety of your consumers.

If you are a manufacturer or business seeking smart packaging, look no further. Our team possesses the knowledge, experience, and expertise to help you find the best tailored solution.

Reach out today, and we will provide you with customized support for a smooth process. We are your one-stop solution to combat counterfeiting and create a secure environment for your business. With reduced counterfeiting, maintain sales and boost customer trust.

Stay proactive, stay vigilant, and invest in effective anti-counterfeit solutions for a counterfeit-free future.

About Lasersec Technologies

We are a leading manufacturer of holographic solutions designed to combat counterfeiting. Our dedicated R&D team continuously seeks innovative solutions, ensuring that all our offerings are original and free from external interference. With successful business alliances in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, the United Kingdom, and across Europe, we are committed to enhancing product security worldwide.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.

-footer.png)